OEM Customized Precision Frame Stainless Steel Aluminum Stamping Bending Welding Laser Cutting Sheet Enclosure Fabrication Service for Molds Chassis Base

Overview Package Size 20.00cm * 20.00cm * 10.00cm Package Gross Weight 1.000kg Surface Treatment Quality Control System

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | E20201S |

| Customized | Customized |

| Material | Metal |

| Application | Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Quote Time | Within 24 Hours or Even Less |

| OEM/ODM | Yes |

| Drawing Format | Pdf/Step/Igs/Solidworks |

| Surface Treatment | Polish, Anodize, Painting, Powder Coating,and etc |

| Shipping Way | DHL, FedEx, UPS, or by Sea |

| Package | PE Foam+Carton+Pallet, or Be Customized. |

| Export Markets | Global |

| Lead Time | 3 to 15 Days Based on Order Qty |

| QC Control | 100% Inspection Before Shipment |

| Tolerance | 0.1-0.5mm |

| Description | Serve to All Kinds of Industry |

| Process | Laser Cutting, Bending, Welding, Polish |

| Service | Rapid Prototype, Low-Volume and Mass Production |

| Surface Finish | Powder Coated, Sand Blasted, Passivate, Anodizing |

| Part Name | Sheet Metal Parts |

| Transport Package | PE Foam + Carton/Wooden Case |

| Specification | Custom size |

| Trademark | OEM/ODM |

| Origin | Suzhou, China |

| HS Code | 84799090 |

| Production Capacity | 15000PCS/Month |

Packaging & Delivery

Package Size 20.00cm * 20.00cm * 10.00cm Package Gross Weight 1.000kgProduct Description

| Part Details (Sheet Metal Processing) | ||

| Metal Materia: | Stainless Steel sheet, Galvanized sheet, Aluminum Plate, Cold Plate, Iron plate, Pickling plate | |

| Machine: |

| |

| Features: | Customized Design ;Sample Order Accepted Short Delivery time; Competitive Prices Long time quality Insurance; Professional after-sale services | |

| Tolerance: | +/- 0.1mm or special requirements. | |

| Main Process: | Sheet metal processing, Bending, Welding. | |

| Surface Finishing: | Brushing, Polishing, Electrophoresis, Anodized, Powder Coating, Plating, Silk screen, Laser Engraving | |

| Application: | Auto /Moto Parts, Machinery Parts, Lighting Components, Hardware Accessories, Electric Motor Products | |

| Packing Details: | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton | |

| Delivery Time: | Prototype sample 5-7days, Mass production: 14-21days | |

| Quality Control System: | Incoming inspection, process inspection, finished product inspection, delivery inspection | |

| We Only Support Custom CNC Machining Parts Order (Non- Standard Parts) | ||

| 1 | Application: | Auto/Moto Parts, Machinery Parts, Lighting Components, Hardware Accessories, Electric Motor Products, etc |

| Agricultural Machinery, Home Appliances, Furniture Hardware, Medical Equipment | ||

| 2 | Materials: | Metals: Aluminum, Stainless Steel, Brass, Copper, Titanium, Mild steel, Tool Steel, Inconel |

| Plastic: POM(Derlin/Acetal), Nylon, ABS, PEEK, Polycarbonate, Polythylene, PVC, PMMA(Arcylic), PET, Polypropylene | ||

| 3 | Machining: | Cleaning, Turning, Milling, Drilling, Grinding,Sheet Metal,Welding,Cutting,Discharge,3D Printing etc |

| 4 | SurfaceTreatment: | Polishing, Deburring, Chrome Plate, Ni Plated, Zine plated, Silver platinng, etc |

| Clear anodizing, Anodizing black, Carburizing Nitriding, Heat Treatment, etc | ||

| 5 | DRW Format: | DWG, STP, PDF, IGS, STEP, SLDPRT, SLDDRW, PRT, DRW, DXF, X_T |

| 6 | DetectionEquipment: | Hexagon CMM, Height Gauge, Two dimensional image measuring instrument, |

| Projector, Micrometer, etc | ||

| 7 | QC System: | 100% Inspection before shipmentIQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training. |

| 8 | Certification: | ISO9001: 2008; ISO13485; AS9100 |

| 9 | Payment Term: | T/T, LC at sight, PayPal, Credit Card |

| 10 | Trade Terms: | FOB, CFR, EXW |

| 11 | Delivery Time: | 10days for sample, 25days for mass goods |

| 12 | OurAdvantages: | Reliable Quality |

| Moderate Price | ||

| High precision | ||

| DMU,MAZAK, FINUC CNC Machining Centres, all of enquipments were imported from Japan/Germany | ||

| Professional Engineers team with full experience | ||

| On-Time Delivery | ||

Surface Treatment

| As machined(Ra 3.2μm, 126μin) | Smooth machining (Ra1.6µm,63 µin) | Brushed(1.2 Ra μm/47 Ra μin) | Powder coated | Bead blasted | Polishing (0.8 Raμm/32 Ra μin) |

| Black oxide | Chromate Conversion Coating (Alodine) | Chromate Conversion Coating (Alodine) | Bead blasted + Anodized type II (Matte) | Anodized type III (Hardcoat) | Brushed + Electropolished (Ra0.8µm, 32µin) |

Quality Control System

| Quality Management Standards | |

| 1. Inspection Standard: | GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL) |

| 2. Quality Control System: | Incoming inspection, process inspection, finished product inspection, delivery inspection |

| 3. 5M1E: | Man, Machine, Material, Method, Measurement; Environment) |

| 4. 5W2H: | Who, What, When, Where, Why; How Often? How Many? |

| 5. 5 Tools for QM: | APQP(Advanced Product Quality Planning), PPAP(Production Part Approval Process), FMEA(Failure Mode and Effects Analysis), MSA(measurement systems analysis), SPC(Statistical process control) |

| 6. PDCA: | Plan, Do, Check, ActionHigh Quality Customized Milling Service Parts Professional Aluminium Cnc Milling Parts |

| 7. Measuring Room Temperature and Humidity Control Range: | 20±2ºC,Humidity: 25~75%RHigh Quality Customized Milling Service Parts Professional Aluminium Cnc Milling Parts |

Our Advantages

| Quickly Response | Quoting within 12-24hours |

| Sample 5-7days | |

| Full Ranges of Fabrication Service | Include CNC Turning&Milling, Sheet Metal parts, Die-casting parts, Surface Finishing |

| Quality Control | Inspection Standard: GB/T 1804-2000, GB/T 1184-1996(No tolerance for shape and position),HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL) |

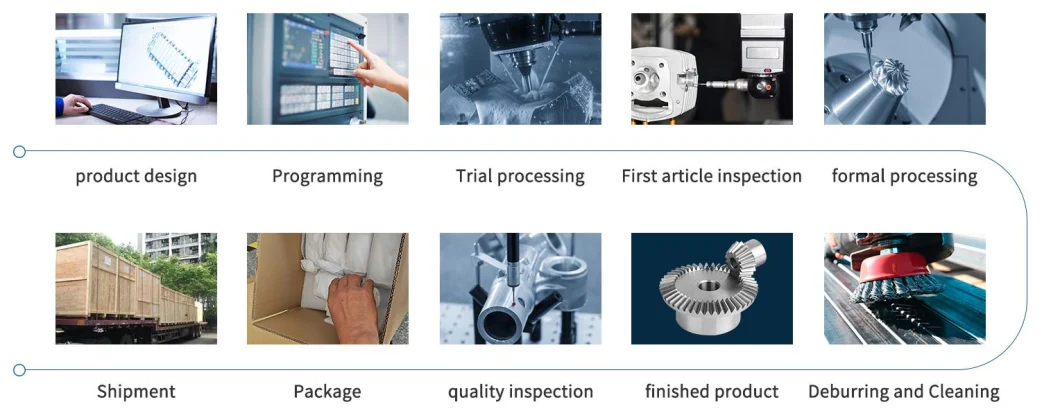

Production Process

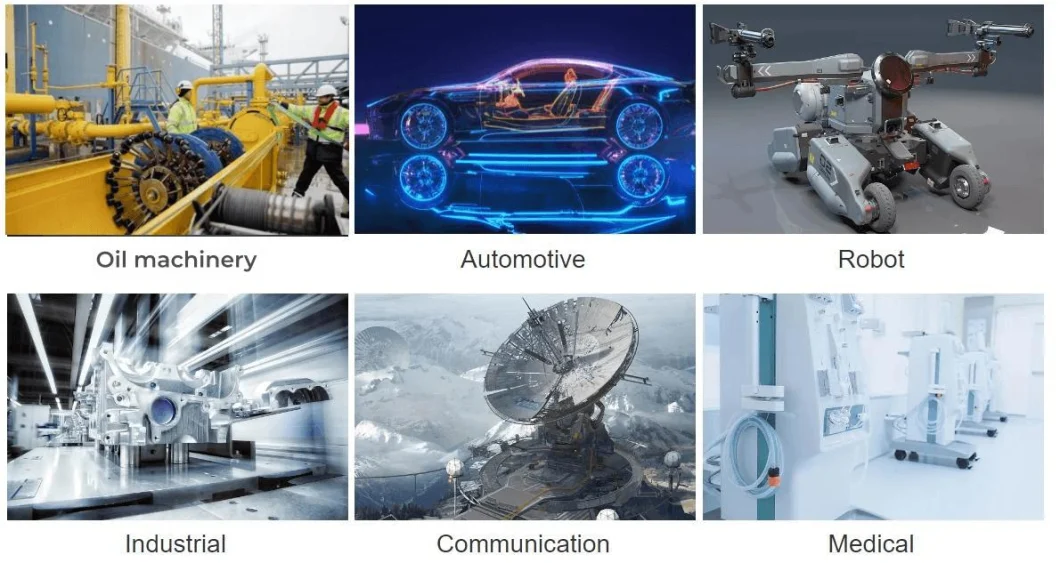

Application

Company Profile

Our Manufacturing Capability

Exhibition

FAQ

Q1: What materials do you machine?

A: We machine aluminum, brass, copper, carbon steel, stainless steel, alloy or plastics like: Acetal, CPVC, Delrin®, Duratron, PAI®, ETFE, FEP, Fluorosint®, Halar®, Kynar®, Neoflon®, Nylatron®, Nylon, PCTFE, Peek, Polyimide, Polyurethane, PVC, Rulon®, Ryton®, Semitron®, Techtron®, Tefzel®, Torlon®, Turcite®, UHMW, Ultem®, Vespel®, Kel-F®High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ2: What kind of machines do you have?

A: We have vertical machining centers and horizontal turning centers with spindles used for tight-tolerances milling and turning, such as tool & die work.High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ3: I need a CNC machining quote; what kind of machining services do you offer?

A: We do the following services: milling, turning, drilling, threading, tapping, part design, prototyping, reverse engineering, low volume or one-off part machine runs, modification of an existing part, material sourcing assistance, limited material warehousing and parts dispatching. To receive a quote, just send a STEP/PDF file via email to usHigh Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ4: What are your hours of operation?

A: We are available Monday through Friday between 8:30 am and 5:30 pm EST. You may always email your CAD (computer-aided design) files along with the necessary information to us High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ5: Which industries use your CNC machine shop services?

A: We serve the Medical device industry, Automobile part industry, Aerospace industry, Automotive industry, Smart Robot industry, Agricultural equipment industry, Food machinery industry… we are open to extend our machine shop assistance to more industries.High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ6: What type of files do you accept?We accept different computer drawing file formats:-STEP (.step) or STP (.stp) formats are ok, but are inferior to the format types above-IGES (.iges) and IGS (.igs) are ok but inferior to the formats above-For Autocad users, DXF/DWG files will work fineHigh Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ7: What is your lead time?

A: This is a situation-specific topic to be discussed once we have a clear understanding of what needs to be done. We work on a first come first serve basis therefore current work load will factor in. After the receipt of a purchase order in writing, file completed, and materials are available, we could say Five business days to Four weeks lead time. This will be subject to the complexity of the parts and quantities of the parts ordered.High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ8: Do you accept small quantity jobs?

A: We are geared toward production but we gladly accept small quantities. You may order one part or thousands. We do view each order individually therefore larger orders will automatically receive a price reduction. We do have a minimum dollar amount per order.High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ9: Why do you need a CAD drawing to cut a simple rectangle, circle or letters?

A: Even the simplest of shapes require a CAD drawing. That CAD drawing will be imported into CAM (computer-aided manufacturing) software. From that drawing, we would utilize the geometry to apply toolpath to all entities intended to be machined. We also want to avoid the liability of cutting something that wasn't approved.A CNC machine is a computer-controlled cutting machine used in the manufacturing world. It involves the use of computers to control the machine tools via G-code. Therefore, only a CAD drawing could be used in the CAM software that both gives us a visual representation and controls the machine.High Quality Customized Milling Service Parts Professional Aluminium Cnc Milling PartsQ10: Why do you need to design and machine a workholding component to machine my parts?

A: CNC machines move at a very high rate of speed combined with a massive amount of torque. Maintaining the desired fixed position throughout the force of cutting ensures repeatable results. If the part moves while being machined, the high tolerances of the part will be compromised. Therefore machining a "jig" or workholding fixture may be required in order to complete the part.

Related Products

-

![Aluminum Tube 6063 6061 7075 T5 Anodized Aluminum Pipe / Anodized Aluminum Tubing]()

Aluminum Tube 6063 6061 7075 T5 Anodized Aluminum Pipe / Anodized Aluminum Tubing

-

![Ace Hardware Bender A/C Aluminum Tubing for Air Compressor]()

Ace Hardware Bender A/C Aluminum Tubing for Air Compressor

-

![Custom Steel Structure Weldment Metal Parts Bending Welding Fabrication Frame Construction Services]()

Custom Steel Structure Weldment Metal Parts Bending Welding Fabrication Frame Construction Services

-

![Customized Aluminium Angle Part for Bending Laser Cutting Part POS Payment Bracket]()

Customized Aluminium Angle Part for Bending Laser Cutting Part POS Payment Bracket